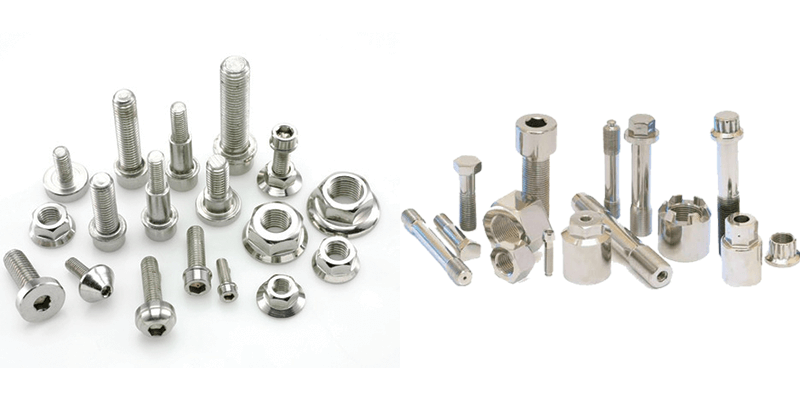

FASTENERS

high quality product

We produce FASTENERS, NUTS, BOLTS, WASHERS, ANCHOR & FASTENERS, STUD BOLTS AND THREADED ROD

When quality matters

We’re a major producer and exporter flanges, we bring quality to your construction site.

We are experienced in the manufacturing of fasteners, such as nuts, bolts, washers, anchor & fasteners, stud bolts, threaded rod. They are manufactured utilizing high grades, such as Stainless Steel, Carbon Steel, duplex steel, monel, inconel, hastelloy, titanium and nickel alloy, which assures their high tensile strength and corrosion resistance. They are used in numerous industries and we offer various sizes ranging from M4 TO M100, length up to 5 meters as per the clients requirements.

Some Features Includes

- Severe vibration under impulse pressure

- Static pressure

- High tolerance

- Dimensional preciseness

- Corrosion resistance

- Perfect installation & application

- Longservice life

- Study construction

- Fast performance

our product types

Bolts, Nuts, Washers, Anchor, Stud Bolts, Eye Bolt, Stud, Threaded Rod, Cotter Pin, Socket Screw, Fine Fasteners & Spares, Foundation, etc

Stainless Steel Fasteners

GRADE AVAILABLE:

ASTM / ASME A 193 B 8( 304) B 8C( SS 347) B 8M (SS 316) B 8 T(SS 321), A 2, A 4 ASTM / ASME A 194 B 8 (304), B 8C ( SS 347), B 8M (SS 316), B 8T (SS 321)

Alloy Steel Fasteners

GRADE AVAILABLE:

ASTM / ASME A 193 B 6, B 7/ B 7M, B 16// ASTM / ASME A 194 GR. 2, 2HM, 2H, GR 6, B 7, B 7M.

Carbon Steel Fasteners

FEATURES:

- Precisely machined

- Corrosion resistant

- Impact absorbing

- Easy to fit

APPLICATION AREAS:

- Pipe and Tubing Industry

- Engineering Industry

- Water Treatment Industry

- Oil and Gas Industry

- Construction Industry

- Petrochemical Industry

- S32205

Duplex Steel Fasteners

FEATURES:

- Robust construction

- Accurate dimensions

- Resistant to corrosion

- Durable

APPLICATION AREAS:

- Engineering Industry

- Water Treatment Industry

- Oil and Gas Industry

- Petrochemical Industry

- Pipe and Tubing Industry

- Construction Industry

Chemical Comositions of Stainlees Steel Fasteners:

| Grade | Chemical Composition1 (% maxima unless stated) | Notes | Alternative names | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Mo | Ni | Cu | |||

| A1 | 0.12 | 1 | 6.5 | 0.2 | 0.15/0.35 | 16-19 | 0.7 | 5-10 | 1.75-2.25 | 2 3 4 | 303S31, 303S42, 1.4305 |

| A2 | 0.1 | 1 | 2 | 0.05 | 0.03 | 15-20 | -5 | 8-19 | 4 | 6 7 | 304, 394S17 (BS 3111), 1.4301, 1.4567 |

| A3 | 0.08 | 1 | 2 | 0.045 | 0.03 | 17-19 | -5 | 9-12 | 1 | 8 | 321, 1.4541, 347, 1.4550 |

| A4 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16-18.5 | 2-3 | 10-15 | 4 | 7 9 | 316, 1.4401, 1.4578 |

| A5 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16-18.5 | 2-3 | 10.5-14 | 1 | 8 9 | 316Ti, 1.4571, 316Cb, 1.4580 |

| C1 | 0.09-0.15 | 1 | 1 | 0.05 | 0.03 | 11.5-14 | - | 1 | - | 9 | 410, 1.4006 |

| C3 | 0.17-0.25 | 1 | 1 | 0.04 | 0.03 | 16-18 | - | 1.5-2.5 | - | 431, 1.4057 | |

| C4 | 0.08-0.15 | 1 | 1.5 | 0.06 | 0.15-0.35 | 12-14 | 0.6 | 1 | 2 9 | 416, 1.4005 | |

| F1 | 0.12 | 1 | 1 | 0.04 | 0.03 | 15-18 | -10 | 1 | 11 12 |

430, 1.4016, 430Ti, 1.4520 430Cb, 1.4511 |

|

Mechanical composition of stainless steel fasteners.

| Steel Group | Steel Grade | Property Class | Tensile Strength Rm1 min MPa | 0.2% Proof Stress Rp0.21 min MPa | Elongation A2 min mm |

| Austenitic |

A1, A2, A3, A4, A5 |

50 | 500 | 210 | 0.6d |

| 70 | 700 | 450 | 0.4d | ||

| 80 | 800 | 600 | 0.3d |